Maintenance Process Management

Roles and Responsibilities

The following roles and responsibilities are distinguished in the Brightly Assetic system. Each role is related to a security profile in the system which will allow a user only to see the information that is related to the role. Depending on the organisational requirements a user can have multiple roles assigned e.g. planner and scheduler may be the same person.

|

Role |

Responsibilities |

|

Requestor |

Anyone who requests maintenance in a structured way following the work request process/es. |

|

Work Request Gatekeeper |

Responsible for assessment of work requests. The gatekeeper approves or rejects the work request. |

|

Work Order Gatekeeper |

Responsible for assessment of work orders. The gatekeeper approves or rejects the planned work order |

|

Planner |

Responsible for the planning of work orders (approved work requests).The result of work order planning must be a complete work package ready to be scheduled and executed. |

|

Scheduler |

Responsible for scheduling of planned work in time. Scheduling will be done in collaboration with operations. |

|

Coordinator |

Responsible for the daily work assignment of the technical resource. |

|

Supervisor |

Responsible for the operational lead of the execution of planned and unplanned work. The supervisor aims for quality, effectiveness and efficiency in the execution of work. |

|

Technician |

Responsible for the execution of work. |

|

Maintenance Manager |

Responsible for overviewing all maintenance activities on an operational, tactical and strategic level. |

Status Driven Work Flows

To indicate where a Work Request or Work Order is in the workflow process, different statuses are displayed. The status flows are as below:

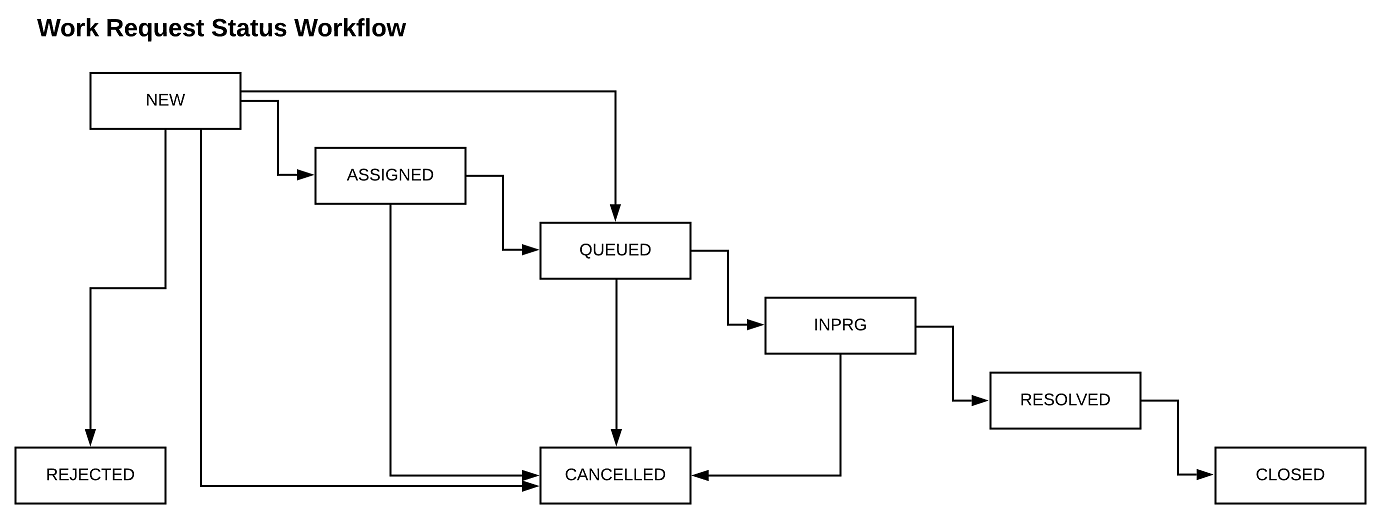

Work Request

The Work Request process is the communication between a customer and the service desk of an organisation. The work request record has its own unique number and will be used as a reference between the customer and the service desk. The different statuses of the work request will identify the progress of the work request. A work request has the following statuses:

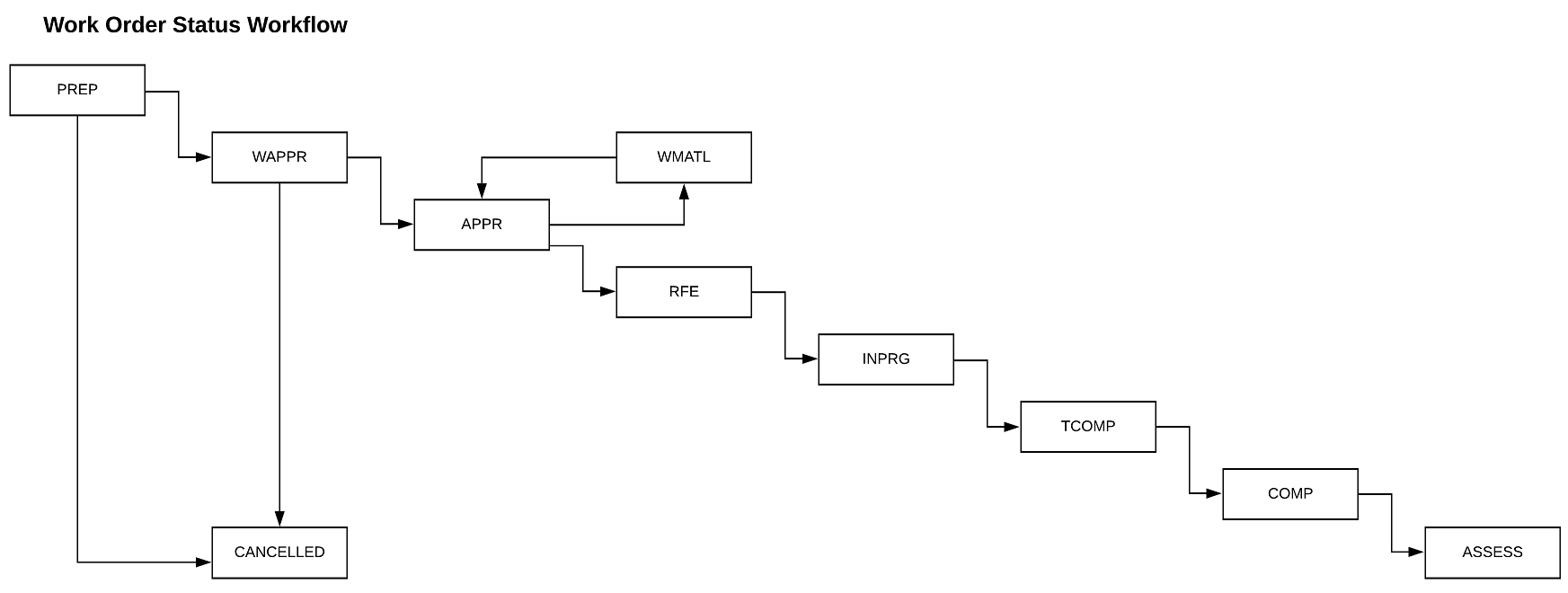

Work Orders

The Work Order process is the internal communication within the organisation and with external contractors with regards to upcoming work. The work order process manages the process of raising a work order, through to the completion and assessment of the work order for continuous improvement. The work order record has its own unique number and can be linked to either a single or multiple work requests. The different statuses of the work order identify the progress of the work order.

A work order has the following statuses:

NOTE If the Adaptive Workflow feature is enabled, the WMATL status is not available, and Work Orders can bypass intermediate statuses if the appropriate fields are correctly populated.

Leading Characteristics

Work Request Type

Work Requests have their own request types to divide the Work Requests into different groups. A Work Request is the communication between the customer and an organisation's service desk. If a Work Request is accepted, a new related Work Order will be created, or the Work Request will be linked to an existing Work Order, which will manage the internal communication inside the organisation’s maintenance department, or with an external contractor. Customers could contact the service desk to check the progress of their request, and the service desk would be able to inform the customer about the progress based on the status of the related work order.

A Work Request can be one of 3 Types:

-

Incident: These are events that may affect customers, the community or cause a danger to health, safety, or the environment

-

Problem: A functional question, defect or breakdown that may affect operations

-

Change: Request for modification to improve, i.e. safety to minimise risks

Work Order Type

The Work Order types are different from the request types and identify the type of work that will be executed. The work types will allow an organisation to group work or prioritise work and are linked to different budget groups within an organisation.

|

Preventive Maintenance (PM) |

|

|

Periodic |

Periodic maintenance to prevent technical failure of an asset |

|

Inspection |

Functional and visual inspection of an asset |

|

Predictive |

Maintenance based on predictive technologies (inspection based on analysis of MTBF), intervals flexible based on inspection analysis |

|

Inspection Action |

Repair following a preventive inspection or from a condition monitoring system |

|

Corrective Maintenance (CM) |

|

|

Assessment |

Assessment of failure before final repair, temporarily fix if possible |

|

Corrective |

Bring failing equipment back to its specified condition (pump failure, pressure not OK) |

|

Follow on |

Final fix following a temporary fix (replace a pump that has been provisorily fixed) |

|

Emergency |

High priority reactive maintenance which requires a fix first, administration afterwards |

|

Modifications (MD) |

|

|

Maintenance Modification |

Modifications to improve maintainability |

|

Non Maintenance |

Modifications for non-maintenance reasons |

|

Projects (PJ) |

|

|

Maintenance |

Projects such as overhauls, replacements and (large) modifications for maintenance |

|

Non Maintenance |

Projects funded externally such as for operations, safety, new environmental legislation etc. |

The different Work Order Types are associated with the different Budget types as laid out in this table.

| Budget Type | Work Order Type |

| OPEX (Maintenance budget) | CM - Assessment |

| CM - Corrective | |

| CM - Emergency | |

| CM - Follow on | |

| MD - Maintenance Modification | |

| PM - Inspection | |

| PM - Inspection Action | |

| PM - Periodic | |

| PM - Predictive | |

| CAPEX (Separate budget for each project) | PJ - Maintenance |

| PJ - Non Maintenance | |

| Other Business Unit (Funded externally) | MD - Non Maintenance |

Work Order Priority

The priority of a Work Order will determine the response time of the work. The priority can be set manually or can be based on the Maintenance Priority Categorisation configuration, which allows for the setup of combinations of Asset Types, Asset Criticality, and Failure Sub Types. The priority, including the response time, will be populated by the system based on this configuration. If required, the priority and the related response time can be overwritten based on individual input.

|

Configuration |

||||

|

Asset category |

Asset criticality |

Problem / Defect |

Suggested priority |

Response time |

|

Pumps |

medium |

3 |

7 days |

|

|

Pumps |

Leakage |

4 |

3 months |

|

|

Pumps |

medium |

Leakage |

2 |

24 hrs |

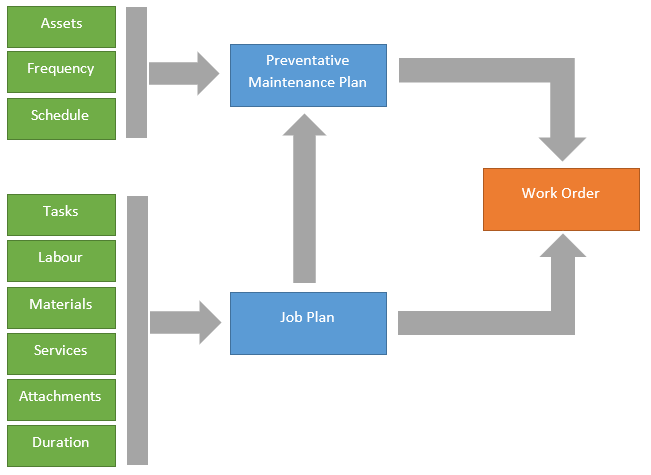

Job Plans, Preventative Maintenance, and Work Order Workflow

Job Plans act as job templates. They are configured to contain the Tasks, Labour, Materials, Services, Attachments, and Duration for Corrective and Preventative Maintenance activities. Job Plans can be applied to Work Orders as a starting point during the work planning phase in the Operational Maintenance workflow. Creating Job Plans for common maintenance activities is good practice and saves time when creating new Work Orders, particularly for Corrective Maintenance.

Job Plans are also required to enable the Tactical Maintenance workflow and are assigned to Preventative Maintenance plans. Preventative Maintenance plans add settings such as Frequency, Schedule, and Assets in addition to the work details provided by Job Plans. Together the Preventative Maintenance plan and Job Plans are combined in the Tactical Maintenance workflow, which is used to automatically generate Work Orders into the maintenance schedule.